The department has traditional and motorised CNC turning centres of various dimensions to cover the largest number of potential processes.

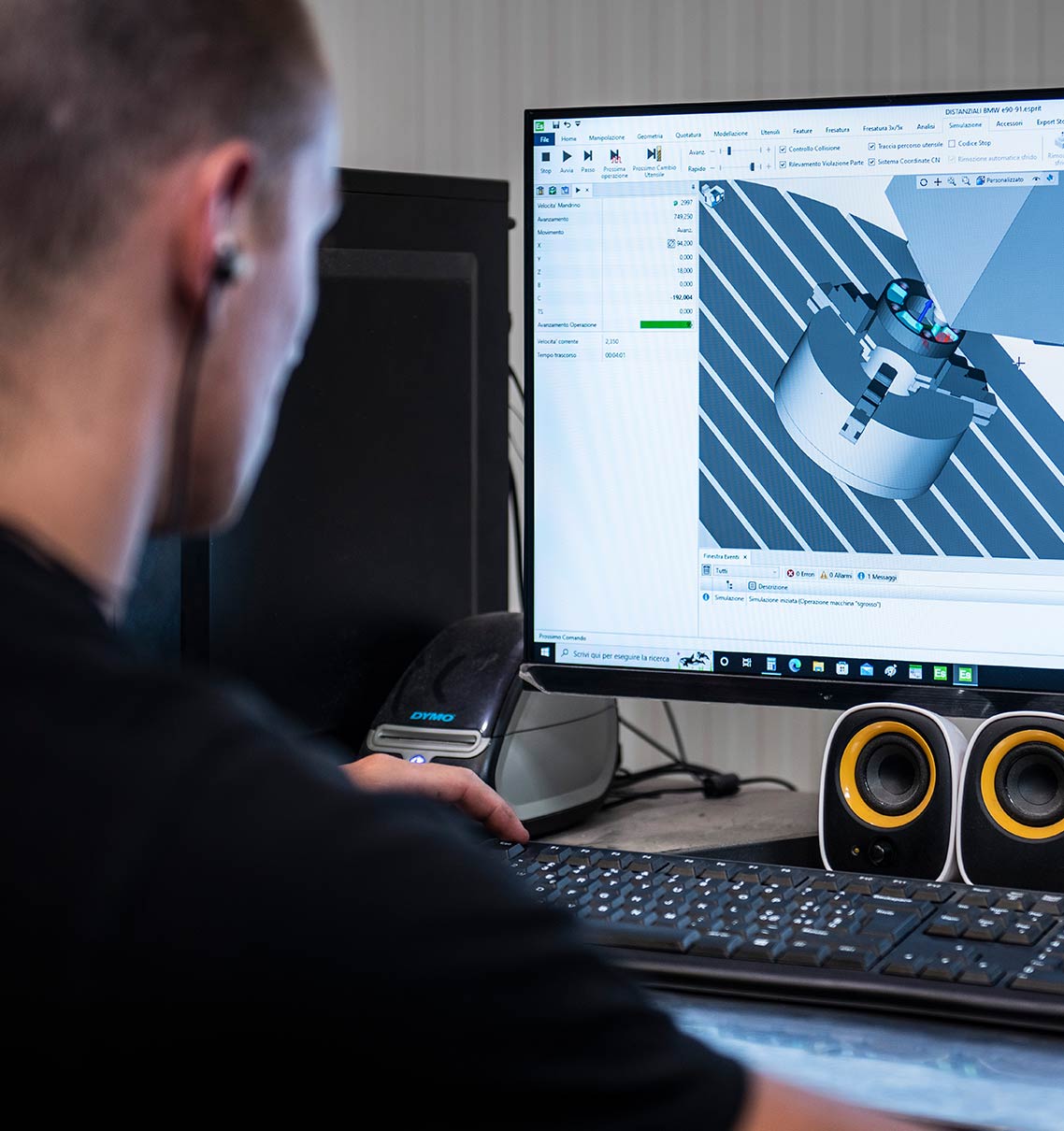

We have horizontal and vertical machining centres: 3/4/5 axes supported by CAM and connected together, making the department efficient and productive.

Large drilling machines, one with 5 axes, enable us to carry out complex operations in all general engineering sectors.

Our sawing machines let us cut very small diameters up to a maximum of Ø810mm, providing an essential service for bespoke solutions.

We have acquired over 40 years of experience in various application sectors, providing customers with guaranteed 360-degree expertise in precision engineering.

We try to use as much energy from renewable sources as possible in our workshop operations. As a result, we have obtained certification issued by CEnPI in relation to green energy.

The owners of the company personally guarantee the quality of their products, from the raw materials through to the finished product. We use accredited primary and secondary tools.

Customers can be safe in the knowledge that our entire production process is carried out internally, ensuring bespoke solutions as required and the highest possible quality. We recently digitalised the complete production process with cutting-edge software technology.

After gaining experience working in engineering workshops, and then in management in the industry, Maurizio established Officina Meccanica R.R.B. srl, a company specialising in precision engineering operations.