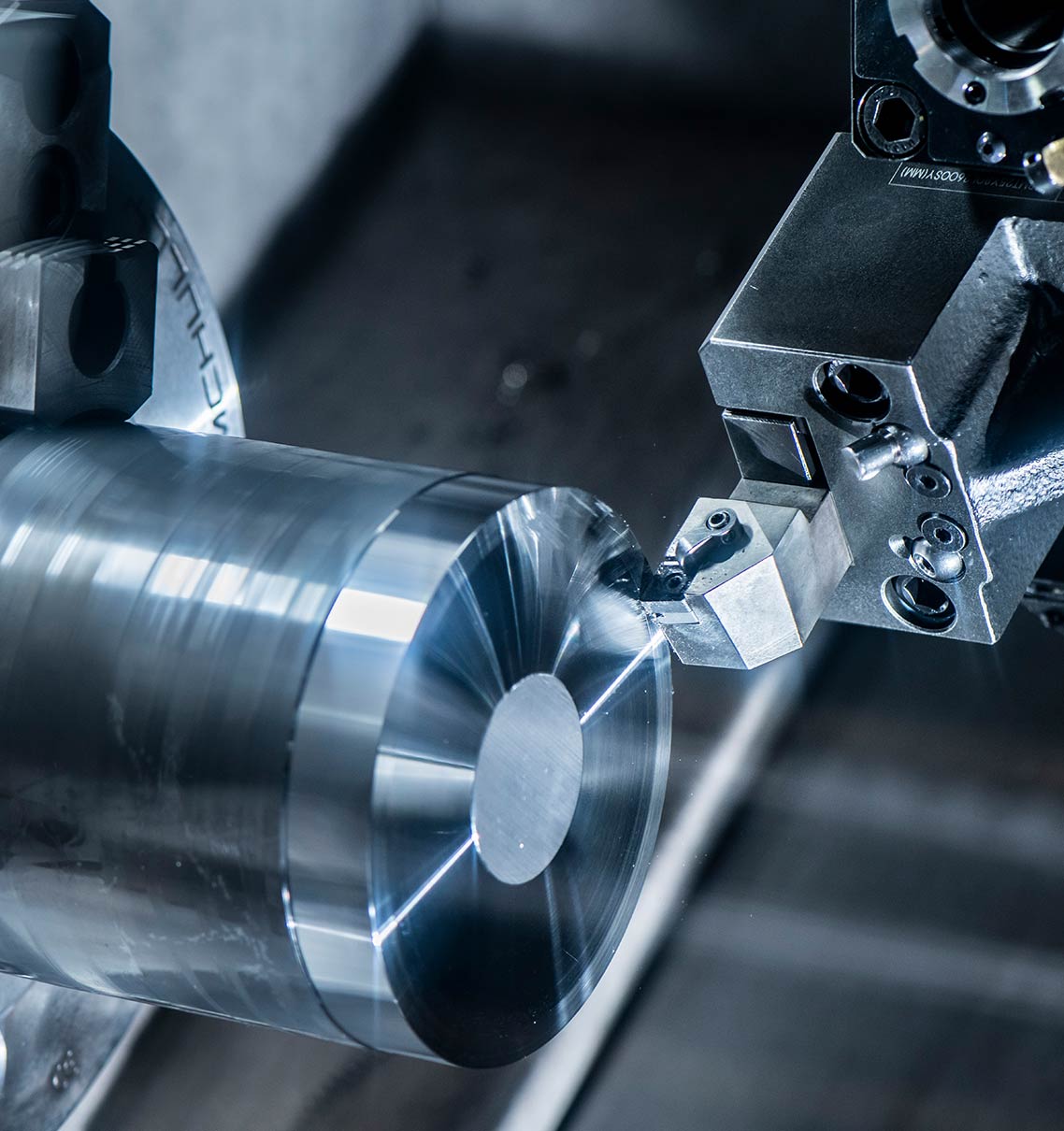

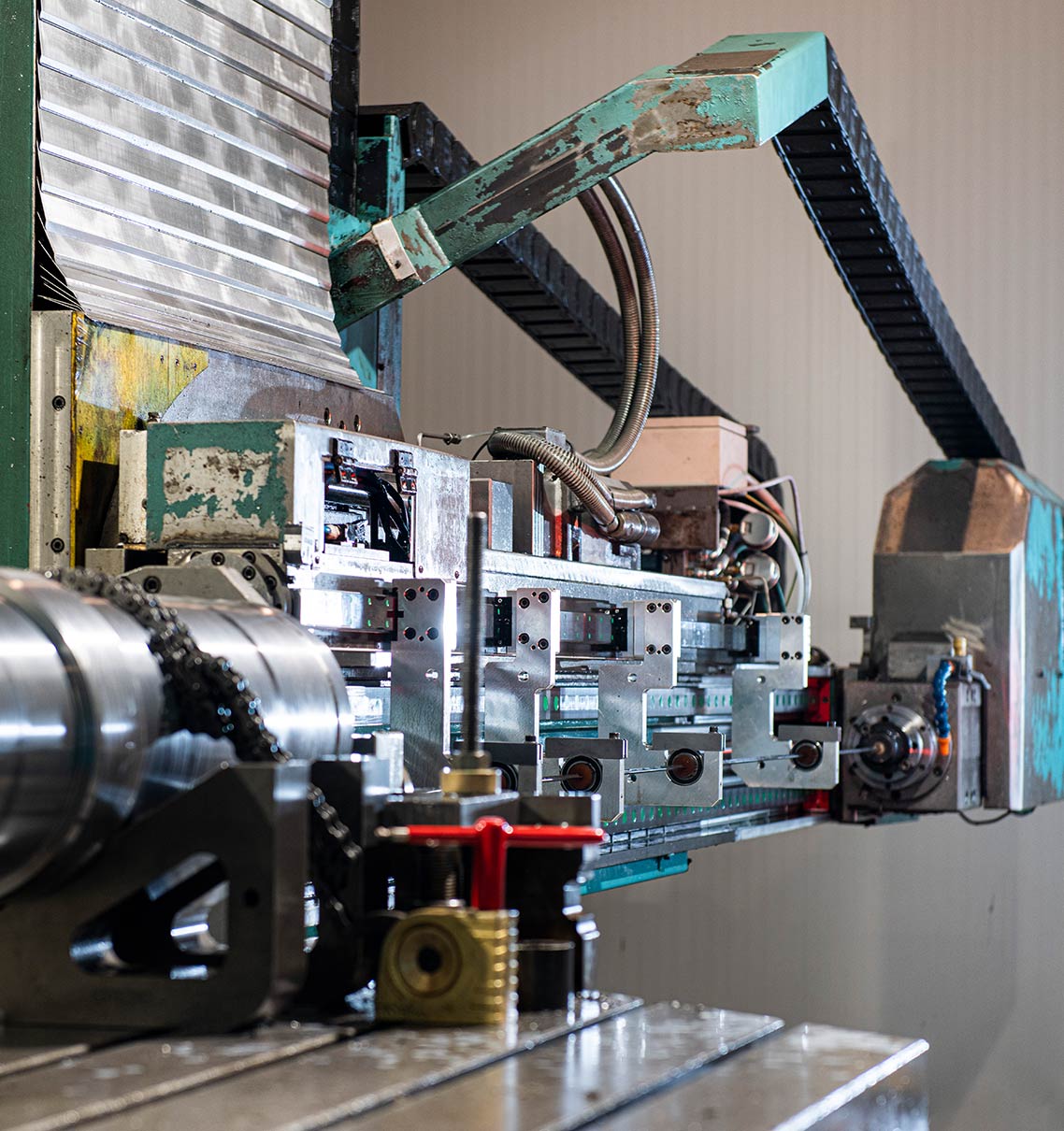

Numerous materials are used in our processes, such as aluminium, ferrous metals, stainless steel, brass, bronze and plastic. The production process is carried out using cutting-edge CNC equipment combined with 3D simulation CAD-CAM software, enabling a significant increase in the complexity of operations and optimising the whole operation.